Structural and Particle Mechanics

Structural Mechanics

Principal Investigator

Eugenio Oñate

Overview

Research

Staff

Projects

The Structural Mechanics Group develops innovative numerical methods combining finite elements with particle-based techniques to analyze structures made of traditional and advanced materials, addressing multi-physics challenges across civil, aerospace, and transportation applications.

The Structural Mechanics Research Group at CIMNE focuses on the development of innovative numerical methods for analysing structural systems across a diverse range of materials, from traditional metals and concrete to advanced composites and hybrid materials. The group’s core expertise lies in creating and enhancing computational techniques that enable accurate prediction of structural behaviour under complex loading and environmental conditions.

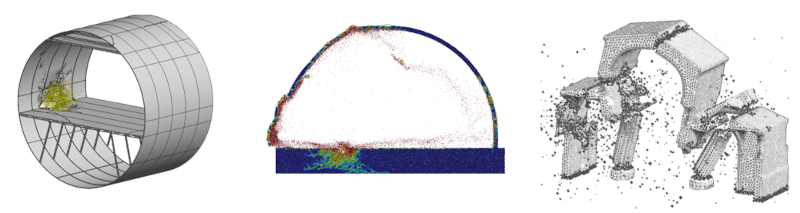

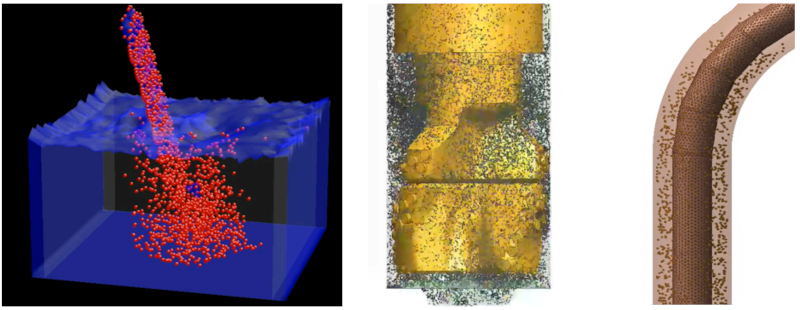

The group employs a versatile computational toolkit that includes the finite element method (FEM) alongside various particle-based computational techniques, such as the discrete element method (DEM) and the particle finite element method (PFEM). A distinctive strength of their approach is the strategic combination of these methods to address multidisciplinary challenges in solid and structural mechanics.

This integrated methodology proves particularly effective for solving multi-physics problems involving thermal-mechanical coupling, fluid-soil-structure interaction, and frictional contact effects. By bridging traditional continuum-based approaches with particle methods, the group creates robust simulation frameworks capable of handling complex material behaviours, large deformations, and dynamic interactions between different physical phenomena.

The group’s research finds applications across numerous engineering sectors, including civil and environmental engineering structures, aerospace components, marine structures, structural elements in surface transport vehicles (cars, trucks, trains, ships), and critical infrastructure in the oil and gas industry. Through these applications, the Structural Mechanics Group contributes to advancing structural design capabilities, performance assessment, and safety analysis across multiple engineering disciplines.

Research areas

Advanced Simulation of Precision Machining

Objective

To improve machining processes through multiscale simulations that account for wear, temperature, and material microstructure.

Innovations

-

- Coupled material–tool models at high speed.

- Integration of thermomechanics, damage, and friction at the contact interface.

- Prediction of surface roughness and defects with experimental validation.

Project Details

The SUPREAM project enables simulation of material behavior during precision cutting, including thermal effects, microcracks, and material evolution. The simulation adapts to different metallic materials, enhancing the prediction of tool wear and final surface quality.

Impact

Optimization of the machining process, reduction of physical testing, longer tool life, and improved quality of industrial components.

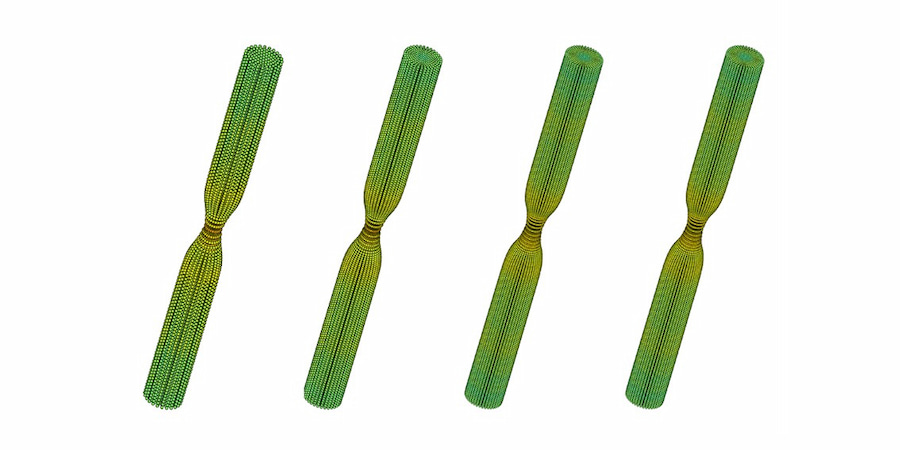

Digital Twin for the Metalforming Industry

Objective

Optimize metal deformation processes by rotation (cylindrical rolling, conical rolling, and spinning).

Innovations

-

- Digital Twin: Advanced simulation for process optimization.

- Sensorized Machines: Cloud connection for continuous data collection.

- Machine Learning: Accelerates predictions and improves parameter calibration accuracy.

Project Details

The OPTIPRO and OPTIREP projects focus on the development and implementation of digital twins to simulate and optimize rolling processes. Through the DENN-data platform, operational data from sensorized machines are collected and integrated into an advanced simulation environment. This enables greater accuracy in the calibration of part parameters, reducing human and material resources. Furthermore, the use of Machine Learning techniques expands the range of analysis and enhances prediction accuracy, optimizing the process in terms of time and cost.

Impact

Significant reduction of resources and increased efficiency, facilitating greater penetration of these technologies in the global market.

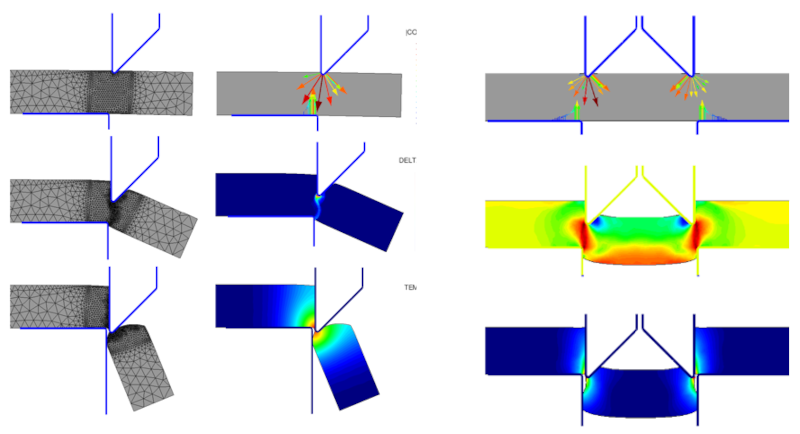

Fatigue Simulation in the Automotive Industry: Fatigue4Light Project

Objective

Improve advanced fatigue simulation in electric vehicle chassis.

Innovations

-

- Fatigue Evaluation: Accurate numerical simulations under various loading conditions.

- Reduction of Physical Prototypes: Optimization of component design and durability.

Project Details

The “Fatigue4Light” project, coordinated by CIMNE, has developed an innovative methodology to assess the fatigue of electric vehicle chassis components through numerical simulations. This technology optimizes the design and durability of components, reducing the need for physical prototypes and lowering both costs and development time. This approach highlights the potential of digital twins to enhance the efficiency and sustainability of electric vehicle production.

Impact

Reduced costs and development time, while improving efficiency and sustainability in electric vehicle production.”

Numerical modeling of the mechanical fatigue phenomenon

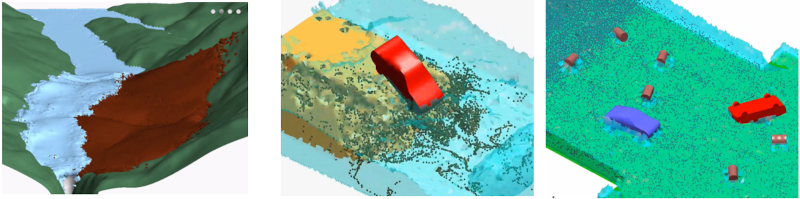

Particle Finite Element Method (PFEM) for multidisciplinary coupled problems in engineering

Applications to the modelling and simulation of environmental problems accounting for fluid-soil-structure interaction. (PIs: A. Franci & E. Oñate)

Finite element methods (FEM) for nonlinear analysis of solids and structures with standard and composite materials

Applications in the building and construction sector and the transport sector. (PIs: X. Martinez, F. Rastellini & E. Oñate)

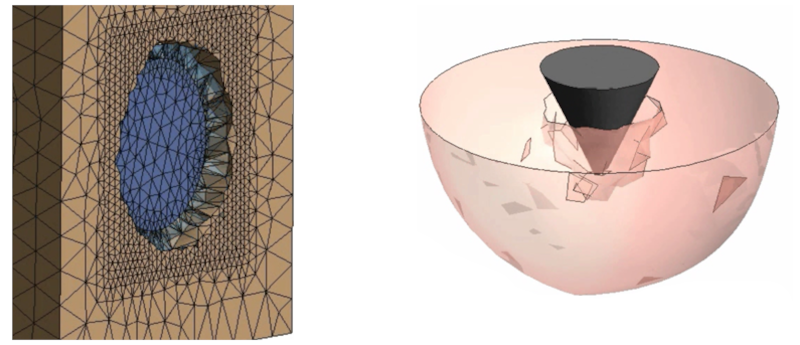

Innovative interface elements for modelling discontinuities in solids

Applications to the flow in fractured porous media and delamination of composites. (PI: I. de Pouplana)

Particle Finite Element Method (PFEM) for multidisciplinary problems in solid mechanics

Applications to the modelling and simulation of machining and blanking processes in the manufacturing industry. (PIs: J. M. Carbonell. & E. Oñate)

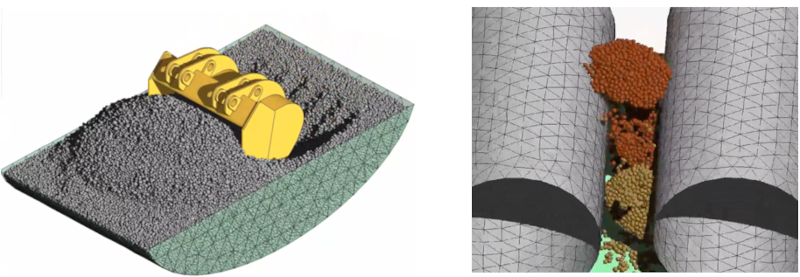

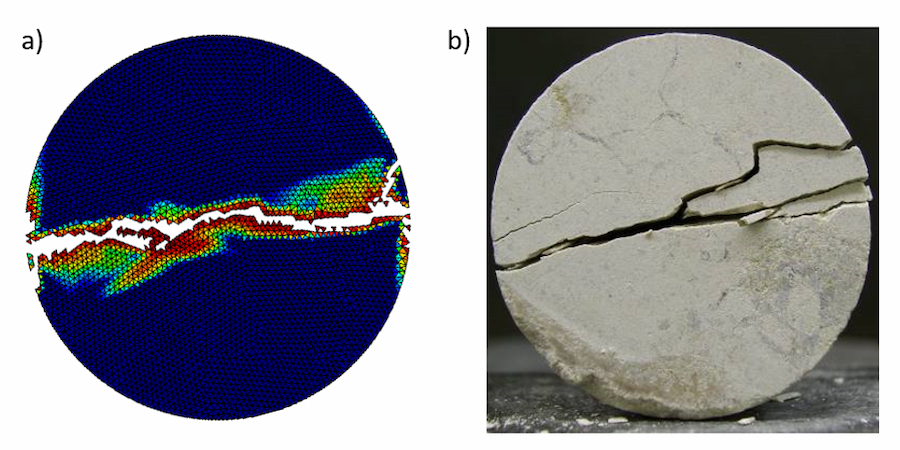

Discrete element methods (DEM) for analysis of non-cohesive and cohesive materials

(PIs: M. A. Celigueta & E. Oñate)

Coupling of DEM, FEM and PFEM procedures

Applications to problems in ground excavation and tunnelling processes and the oil and gas industry. (PIs: M. A. Celigueta, G. Casas & I. de Pouplana)

Finite elements for analysis of plates and shells

Applications in the building and construction sector and the transport sector. (PIs: E. Oñate, F. Rastellini & J. M. González)

Innovative fatigue models accounting for coupled damage and plasticity effects for analysis of structures under high, medium and low cycling loads with the FEM

Applications to fatigue life prediction of metallic components and structures in the automotive industry and concrete structures in the building and construction sector. (PIs: L. Barbu & E. Oñate)

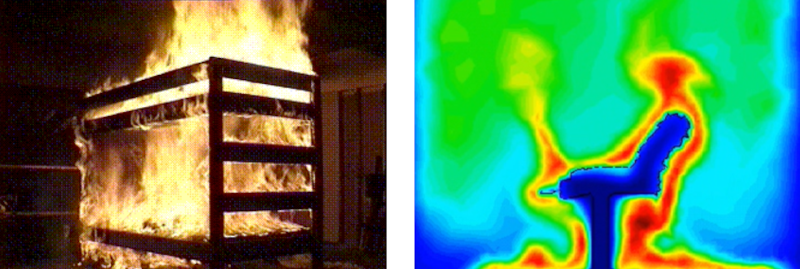

Modelling and simulation of the melting and burning of objects in fire

Applications to the analysis and design of fire retardant polymers. (PIs: J. Marti & E. Oñate)

Particle-based methods for analysis of particulate flows

Applications to the modelling and simulation of suspended particles in fluids. (PIs: S. Idelsohn, E. Oñate & G. Casas)

Numerical methods for accurate and fast solution of problems in continuum and structural mechanics

(PIs: E. Oñate & I. de Pouplana)

Featured Projects

Particle Finite Element Method

A Powerful Tool for Fluid-Structure Interaction and Large Deformation ProblemsThe Particle Finite Element Method (PFEM) is a powerful computational technique developed at CIMNE for solving complex engineering problems involving free-surface flows, large deformations,...

Advanced Modelling for a Sustainable Future

CIMNE experts deliver cutting-edge capabilities in Digital Twins and Complex Modelling technologies. By using sophisticated computational frameworks and machine learning approaches, we develop predictive and management tools that harness the power of aggregated data...

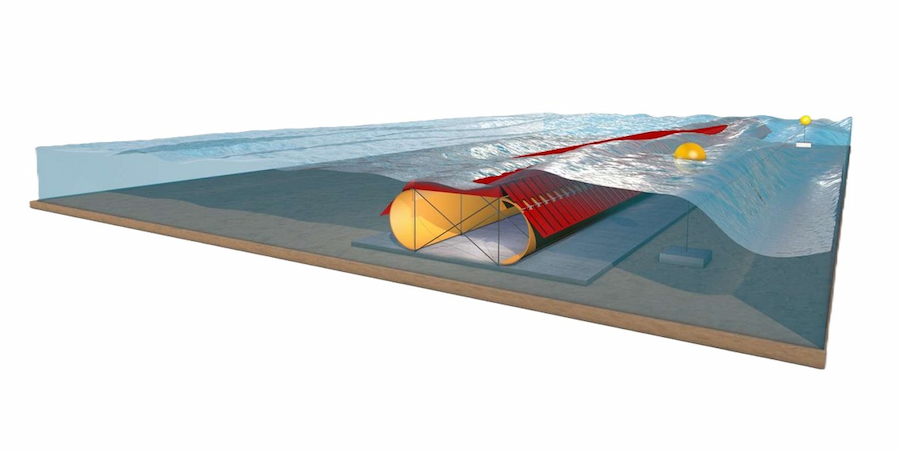

Inflatable Breakwaters for Coastal and River Protection

Inflatable breakwaters are flexible structures that deploy or retract according to flow conditions or environmental requirements. This innovative technology supports an integral management of the coastline to avoid the disappearance of the sand on the coast of the...

PLCd – PLastic Crack dynamic

PLCd (PLastic Crack dynamic) is a finite element code designed for the numerical simulation of nonlinear dynamic behaviour in complex structural systems. It has been developed at the International Centre for Numerical Methods in Engineering (CIMNE) and the Department...

Finished projects

Ongoing projects

Related news

CIMNE at the Mobile World Congress 2026: Digital Solutions, Real-World Impact

March 2-5, 2026 | Fira Gran Via, Barcelona CIMNE's Stand: Hall 8.1, 8.1C12.1 The International Centre for Numerical Methods in Engineering (CIMNE) features innovative simulation and smart solutions in this year's edition of the Mobile World Congress, the world...

CIMNE Showcases Seismic Simulation Advances and VR Innovation at Spanish Nuclear Society’s Annual Meeting

The 51st Annual Meeting of the Spanish Nuclear Society (SNE), held in Cáceres, reaffirmed itself as the key gathering of the nuclear sector in Spain. With 694 participants, 248 papers, 42 technical sessions, 23 exhibitors, and 31 sponsors and collaborators, the...