Solid and fluid simulation for Industrial Processes

Industrial Manufacturing Processes

Principal Investigator

Michele Chiumenti

Overview

Research

Staff

Projects

CIMNE’s Industrial Manufacturing Processes Group develops advanced computational tools for simulating casting, welding, additive manufacturing, and sheet forming. Their software (VULCAN, WELDPACK, ADD2MAN, STAMPACK, HP4FSW) enables high-precision process optimization, bridging academic research and industrial applications worldwide.

The Industrial Manufacturing Processes Research Group at CIMNE specializes in the development of cutting-edge computational methods for the thermo-mechanical modelling and nonlinear analysis of advanced manufacturing processes.

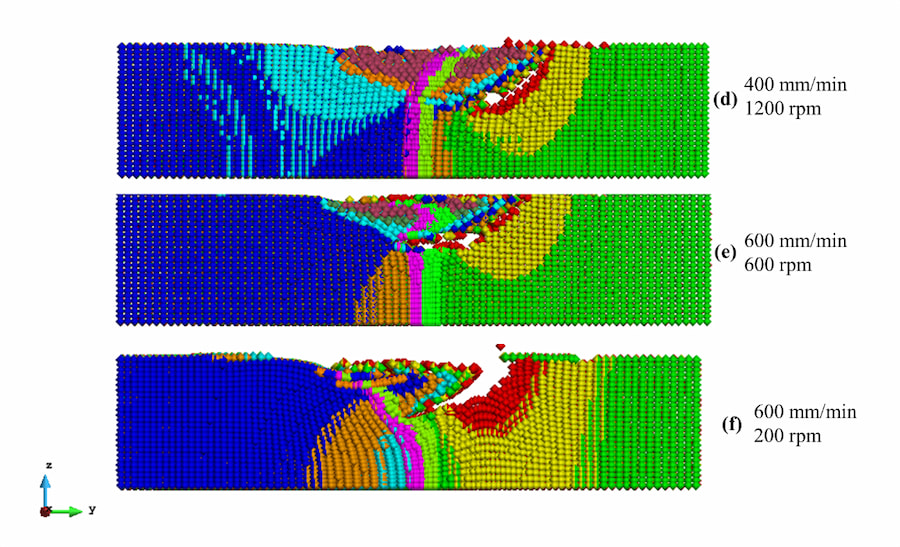

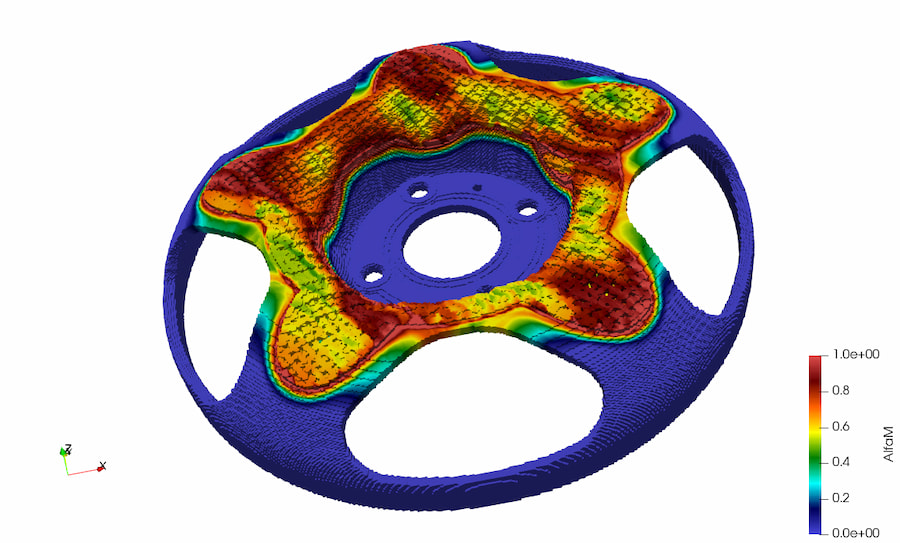

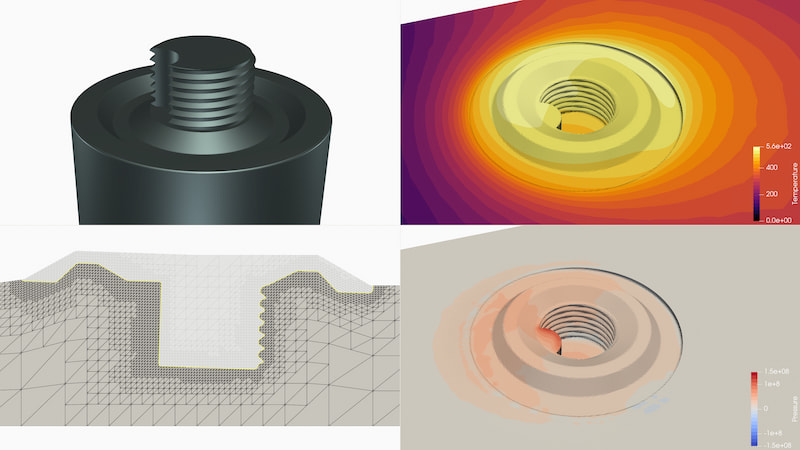

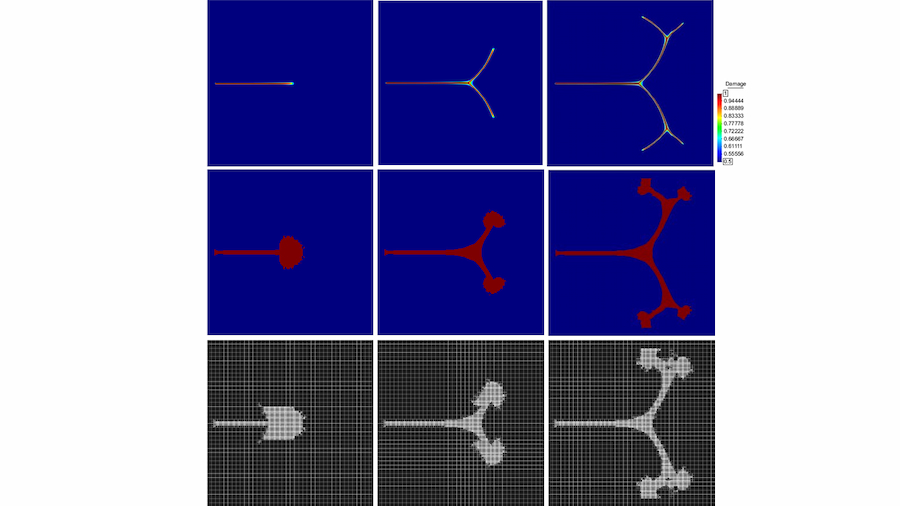

Leveraging finite element techniques, the group pioneers high-fidelity simulations of complex industrial applications—including casting, welding, additive manufacturing, and sheet metal forming—to optimize process efficiency, reduce defects, and enhance material performance.

Core developments are implemented in two in-house finite element platforms: COMET, tailored for high-accuracy academic research, and FEMUSS, designed for robust industrial deployment. Both frameworks incorporate advanced finite element formulations for isochoric and large deformation problems, a comprehensive library of constitutive models including viscoelastoplasticity, damage mechanics, small and large strain plasticity as well as multiphysics features such as thermal coupling and phase-change analysis.

Key commercialized software solutions—such as VULCAN (casting), CLICK2CAST (mold filling), WELDPACK (welding), ADD2MAN (additive manufacturing), HP4FSW (friction stir welding), and STAMPACK (sheet forming)—demonstrate the group’s success in translating theoretical advancements into industry-ready tools. By bridging high-performance computing with real-world manufacturing challenges, the group drives innovation in sectors ranging from automotive and aerospace to energy and heavy machinery, ensuring sustainable, cost-effective production methodologies for the future.

Ongoing projects

Finished projects

Related news

Minister Sàmper visits CIMNE headquarters to explore how computational research drives industry forward

The Minister of Business and Labour, the Honorable Mr. Miquel Sàmper i Rodríguez, together with the Director General for Industry, Mr. Xavier Roca Ramón, have visited this week the headquarters of the International Centre for Numerical Methods in Engineering (CIMNE)...

Desenvolupen un mètode numèric que reforça la fiabilitat de la impressió 3D de formigó

El clúster de Simulació de sòlids i fluids per a processos industrials del CIMNE ha participat en un estudi que proposa un mètode numèric per simular la impressió 3D d’estructures de formigó i les capes que el conformen. Aquest model és una eina valuosa per...