Aeronautical, Marine, Automotive and Energy Engineering

Composites and Advanced Materials for Multifunctional Structures (CAMMS)

Principal Investigator

Fermín Otero

Overview

Research

Staff

Projects

CAMMS develops efficient numerical methods and procedures for the characterization and behaviour prediction of advanced materials, including high-performance composites and novel multifunctional ones. Our tools are applied in the simulation and analysis of large-scale multifunctional structures across the naval, offshore, aerospace, automotive, and civil engineering sectors.

The group has a strong background in the mechanical simulation of fibre-reinforced polymers, using enhanced mixing theories, as well as meso-scale and multiscale formulations, including efficient algorithms for fatigue prediction. The group also has extensive experience in the analysis of fibre-metal laminates, reinforced and prestressed concrete, as well as novel materials with topologically optimised microstructures.

CAMMS’s research is structured around several interconnected lines, including the development of advanced constitutive models for anisotropic damage and plasticity, the formulation of fatigue degradation laws, and the implementation of multiscale and reduced-order model approaches to capture the complex behaviour of heterogeneous materials or substructures.

Additional areas of focus include phase-field modelling techniques, optimisation strategies for material design, and simulation methodologies tailored to additive manufacturing and novel composite architectures.

In addition, the group develops models for delamination without explicit interface representation, implicit frictional contact and tire mechanics, as well as fluid–structure interaction. An emerging line of research is dedicated to biological and bio-based materials, with a particular focus on self-healing polymers such as vitrimers.

Through an established team of multi- and interdisciplinary experts, CAMMS places strong emphasis on computational efficiency, integrating its models into finite element codes to ensure scalability and enable the thermomechanical simulation of large-scale and multi-physics structures. These tools are widely applied in competitive and industry-funded projects across various engineering sectors, aiming to provide innovative, simulation-based design solutions for next-generation multifunctional structures.

Research areas

Constitutive modelling and fatigue simulation of advanced materials

Development of advanced constitutive models for a wide range of materials and structural systems, including composites, prestressed concrete, biological and bio-based materials, and self-healing systems. Special emphasis is placed on fatigue modelling to efficient simulation of cyclic loading, using both phenomenological and multiscale formulations. This line also includes a comprehensive grasp of micromechanical damage mechanisms, anisotropic damage, plasticity, coupled damage–plasticity models, and phase-field methods, as well as zig-zag formulations and advanced approaches for simulating complex failure and degradation processes over time.

Read more

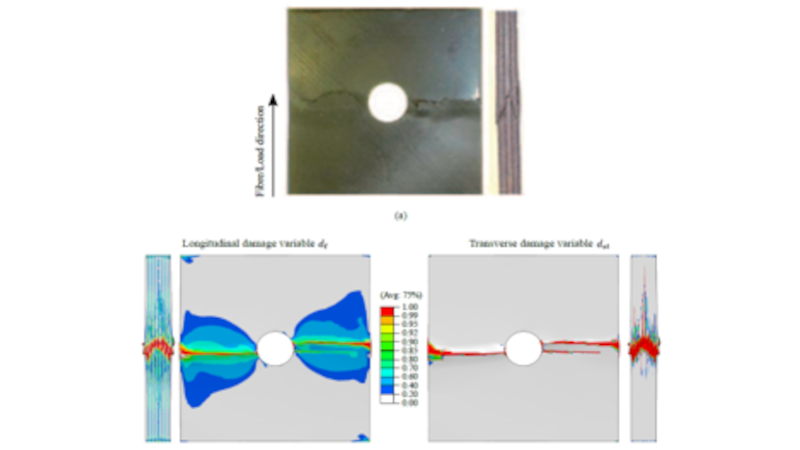

Long fibre reinforced polymer composites

Constitutive modelling and numerical simulation of long fibre reinforced polymer (LFRP) composites, with special emphasis on their orthotropic, rate-dependent and history-dependent behaviour under complex loading conditions. The group develops advanced models that integrate damage and plasticity mechanisms, enabling accurate prediction of progressive failure, including dynamic loading, fatigue and impact events. These formulations include serial/parallel theories, smeared crack models, invariant-based plasticity, orthotropic damage laws, and coupled damage–plasticity models enriched with viscous effects to capture time-dependent phenomena. Particular attention is paid to thermoplastic matrices, due to their relevance in sustainable and high-performance applications. The subline supports the design and certification of lightweight, robust composite components across the aerospace, automotive, marine and energy sectors. Recent developments also incorporate phase-field fracture theories coupled with plasticity to simulate the evolution of microstructural damage in fibre-reinforced composites.

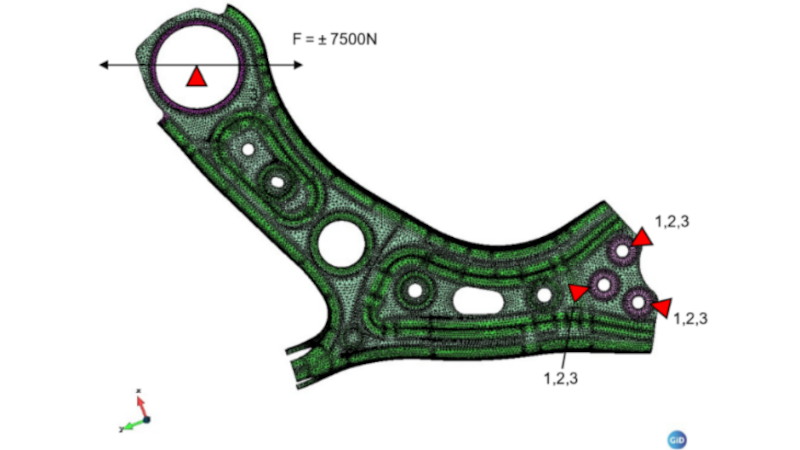

Fatigue degradation modelling

This research aims to provide a comprehensive and unified approach to fatigue analysis, capable of addressing real-world loading scenarios involving variable amplitudes and the coexistence of multiple fatigue regimes. Constitutive models have been developed to cover the full spectrum of fatigue behaviour, from low- to high-cycle fatigue, using both general unified formulations and models specifically tailored to each regime. Particular emphasis is placed on the progressive degradation mechanisms in high-cycle fatigue, including their nonlinearities, and on the modeling of cyclic plasticity accumulation characteristic of low-cycle fatigue. The resulting framework enables accurate fatigue life assessment of specimens, structural components, and mechanical systems under complex multiaxial and variable-amplitude loading conditions.

Biological and bio-based materials, and self-healing systems

Constitutive modelling and numerical simulation of advanced materials inspired by biological systems, with a focus on sustainability, circularity, and extended durability. Research in this area includes self-healing polymers and composites, such as vitrimers, which are capable of recovering mechanical integrity after damage. Computational models simulate the coupled degradation–healing behaviour of these systems, incorporating thermodynamically consistent damage variables, activation functions, and effective healing metrics. These models are validated through experimental studies and implemented in nonlinear finite element frameworks. The subline also investigates the mechanical behaviour of bio-based materials derived from renewable resources, aiming to reduce environmental impact while maintaining high performance. Applications span structural and multifunctional components across the aerospace, automotive, and energy sectors, where repairability and sustainability are key drivers for material innovation.

Advanced zig-zag models for multiscale analysis of composites and innovative materials

Development of advanced zig-zag models for the analysis of multilayered composite structures used in lightweight applications across the aerospace, automotive, marine, and energy sectors. These models are designed to accurately capture the complex through-the-thickness mechanical behaviour of laminated and sandwich structures, improving the predictive capabilities of low-order beam and shell models without increasing computational cost. Current research also addresses the integration of zig-zag kinematics with multiscale homogenization approaches to enable more accurate and robust analysis of composite structures, including the presence of defects, damage mechanisms, and unconventional materials. Particular attention is given to the Finite Element (FE) implementation of these models, with the goal of integrating them into advanced FE frameworks and potentially facilitating their adoption in commercial simulation tools.

Computational tools for multiscale and nonlinear problems

Development and implementation of advanced numerical methods to simulate the complex behaviour of heterogeneous materials and structures. This includes multiscale techniques, reduced-order models (ROM), and efficient solvers for nonlinear phenomena such as thermomechanical coupling, frictional contact, and tire mechanics. The group works extensively with the finite element method (FEM) for solid mechanics (compressible and incompressible), and convection–diffusion problems. Other areas include eigenvalue computations, and coupled solvers for fluid–structure interaction, thermomechanics and thermofluidics. Current research also integrates data-assisted computational mechanics and multiscale second-order homogenization techniques, with applications in materials such as masonry and lattice structures.

Read more

Multiscale simulation of composite materials

This research addresses the numerical simulation of heterogeneous materials through multiscale formulations, aiming to accurately capture the link between microstructural mechanisms and structural-scale response. The group develops enhanced coupling strategies between models operating at different scales, including shell–solid and beam–solid interactions using high-order homogenization techniques, as well as mixed boundary conditions and scale-bridging approaches based on reduced-order modelling. Special attention is given to representative volume element (RVE) formulations for micromechanical analysis, including the simulation of fibre-dominated failure and damage evolution using phase-field models. These tools enable the prediction of complex failure modes with reduced computational cost, while preserving accuracy and robustness across different composite architectures. Overall, this subline supports the efficient and realistic simulation of composite components in high-performance applications.

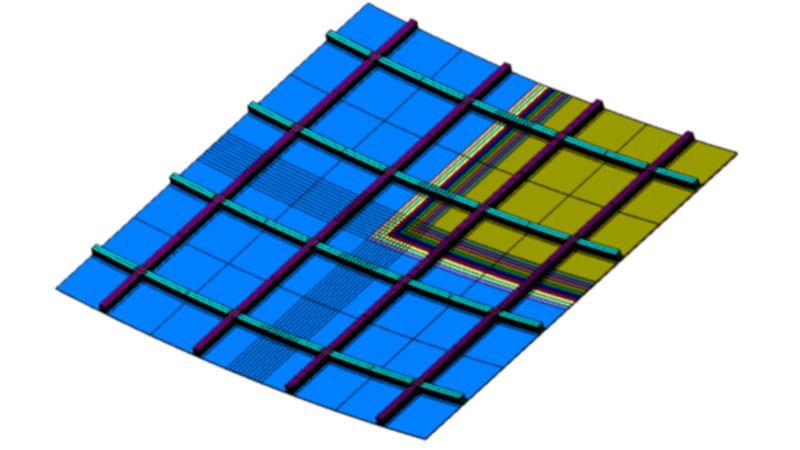

Novel Tailored Superelements for Structural Discontinuities

Development of high computational efficiency in the analysis of large-scale composite structures featuring localized discontinuities, such as reinforcements, cut-outs, laminate transitions, and bonded joints. Regular regions are modeled using conventional beam or shell elements, while zones with irregularities are treated with detailed solid or plane-stress formulations. To bridge these domains, it develops robust interface strategies enabling weak coupling between model types, with particular focus on laminar interfaces with variable stiffness, a hallmark of composite materials. These hybrid modeling approaches also provide the foundation for constructing of superelements using Reduced Order Models (ROMs), whereby detailed representations of irregular zones are numerically characterized and condensed into efficient tailored novel finite element formulations. The ultimate objective is to ensure seamless integration with standard beam and shell models commonly used in industry, facilitating accurate and efficient simulation of complex composite assemblies.

Design, modelling, and optimisation of novel materials for additive manufacturing

Integration advanced optimisation techniques and simulation methodologies to design next-generation materials and structures. It focuses on topology and shape-optimised microstructures and architectures tailored for additive manufacturing, while incorporating process constraints such as minimum feature size, overhang limitations, and build orientation. Detailed modelling of the anisotropic material properties of 3D-printed components ensures accurate performance predictions and robust, manufacturable designs, advancing high-performance, application-driven materials for diverse industries.

Read more

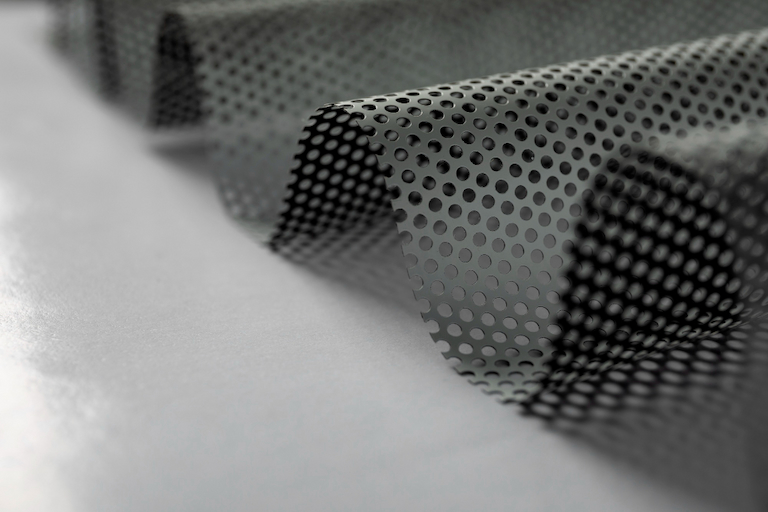

Anisotropic modelling and numerical analysis of 3D printed structures

Accurate modelling and numerical simulation of composite structures manufactured through additive processes. Due to the layer-by-layer deposition and process-induced fibre orientations, 3D-printed materials exhibit strong mechanical and thermal anisotropy, which significantly affects their structural behaviour and performance. The group has developed a mapping-space formulation that can be integrated into any constitutive model to reflect the directional behaviour of resins and fibre-reinforced composites, whether with short or long fibres. It allows for precise simulation of process-dependent effects and supports robust design strategies tailored to the specific characteristics of additive manufacturing. The tool has been successfully applied to the analysis of large-scale printed panels and complex structures such as torsional kirigami systems, enabling reliable prediction of performance and failure. These developments contribute to unlocking the full potential of composite additive manufacturing in high-performance applications.

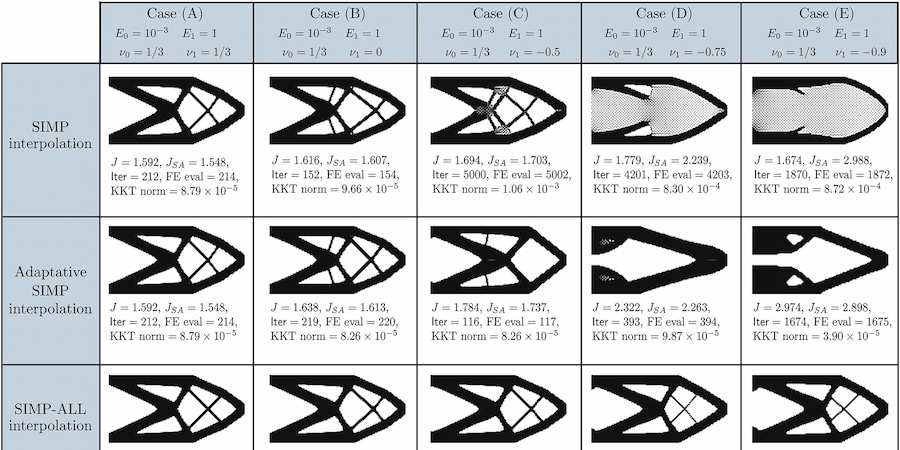

Additive Manufacturing Constraints in Topology Optimization

Integration of additive manufacturing (AM) constraints, such as overhang angles, minimum feature sizes, connectivity requirements, and build orientation, into topology and shape optimization frameworks. By embedding these constraints directly into the design stage, the resulting geometries are not only optimized for mechanical performance but also inherently manufacturable using AM technologies. This integrated approach minimizes the need for post-processing, reduces production risks, and enhances the reliability of the final printed components.

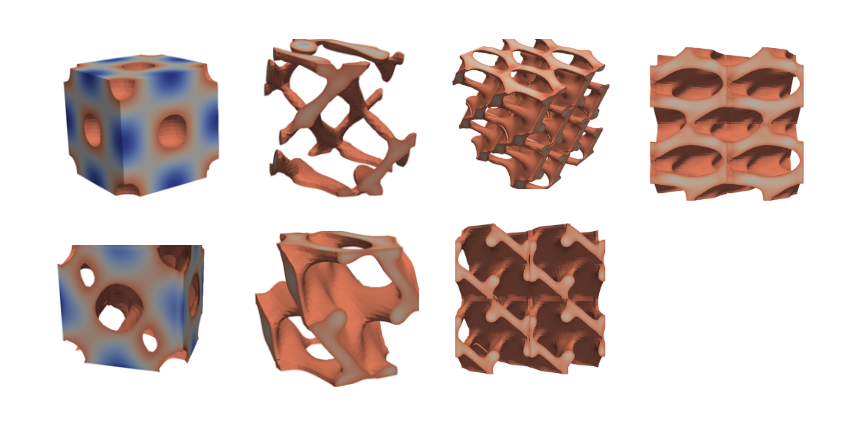

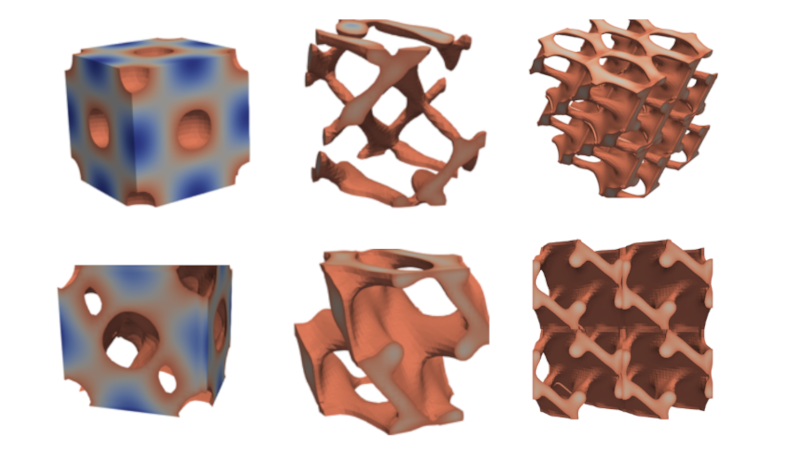

Design of architectured materials, lattice structures, and dehomogenization

Development of architectured materials and lattice structures that are optimized for both mechanical performance and manufacturability. Advanced topology optimization techniques, combined with dehomogenization strategies, are employed to derive optimal microstructural patterns from macroscale design requirements. The resulting lattice configurations can be seamlessly translated into manufacturable geometries, particularly suitable for additive manufacturing processes. This framework enables the tailored design of high-performance materials and structures, accounting for both functional targets and production constraints.

Analysis of advanced and multifunctional engineering structures

The material models and numerical formulations developed by CAMMS group are available for the design, analysis and optimization of advanced multifunctional engineering structures. All formulations are implemented in in-house finite element codes with algorithms that ensure a minimal computational cost, which makes them optimal for the simulation of large structures. The resulting software has been used to investigate and propose new structures, made with advanced materials, that can fulfil specific performance requirements in a wide range of engineering fields including aerospace, aeronautics, marine, industrial, civil, automotive, and energy sectors.

Featured Projects

Advanced aeronautical lightweight structures

Experts at CIMNE’s research group CAMMS (Composites and Advanced Materials for Multifunctional Structures) engineer sustainable solutions tailored to industrial needs. Their research tackles one of today’s major transport challenges by developing advanced lightweight...

PLCd – PLastic Crack dynamic

PLCd (PLastic Crack dynamic) is a finite element code designed for the numerical simulation of nonlinear dynamic behaviour in complex structural systems. It has been developed at the International Centre for Numerical Methods in Engineering (CIMNE) and the Department...

Ongoing projects

Finished projects

Related news

CIMNE and Singular Aircraft sign letter of intent to strengthen collaboration in aeronautical R&D

The International Centre for Numerical Methods in Engineering (CIMNE) and Singular Aircraft have signed a letter of intent framing strategic collaboration in research, development and innovation in the aeronautical field. The document, signed on Tuesday, aims to...

FIBRE4YARDS Project Wins JEC Composites Innovation Award 2025

The FIBRE4YARDS project, led by Xavier Martínez Garcia, a professor at the Faculty of Nautical Studies of Barcelona (FNB) at the UPC and researcher at the International Centre for Numerical Methods in Engineering (CIMNE), has been awarded the prestigious JEC...